Materials

Stainless steel is used to produce all ranges of this product.

Dimensions

For the design, we need to know the existing geometry, the water level and the type of waste. Based on these parameters, we can calculate the size of the most suitable unit, or multiple units can be selected in series.

The following data are necessary for calculating the dimensions of grate cleaners:

- Width and height of the canal.

- Maximum water level from the base of the canal.

- Pitch

- Waste type

- Discharge height measured above the manoeuvring floor.

Technical data

The main parts of the hydraulic grate cleaners are: drive, frame, grate and cleaning system.

Drive

The drive, which can be oil-hydraulic or electric, is responsible for moving the cleaning comb. Transmission options include chain, rack and pinion, or cylinders.

Frame

The main structure is calculated and designed to support the drive and all necessary elements (gears, bearings, etc.) for the proper operation of the grate cleaners.

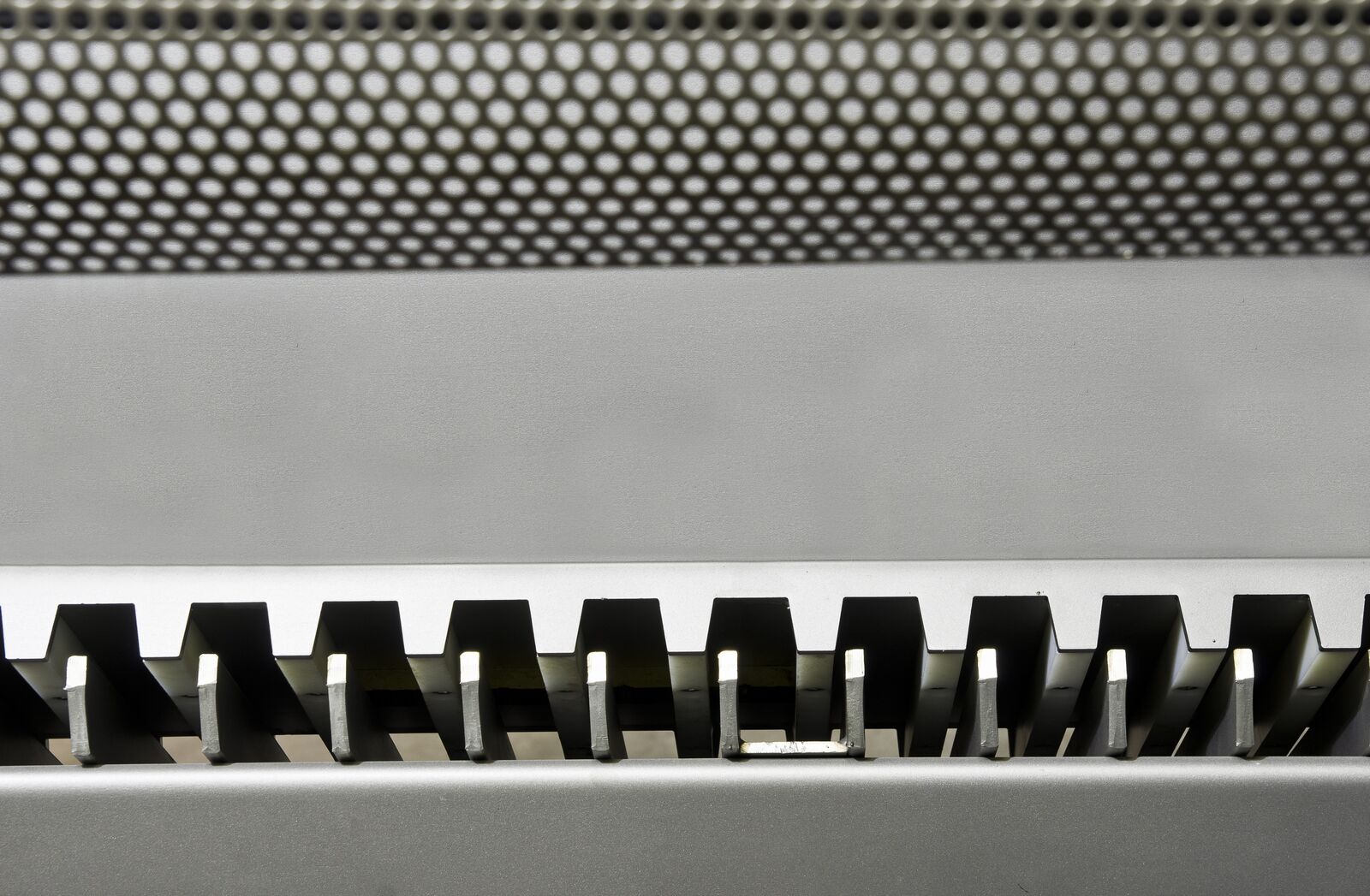

Grate

The bars are arranged with the necessary pitch to support 100% of the hydraulic thrust. Its angle of inclination is greater than that of other grates, as it must retain and remove large volume elements without debris falling from the comb during its upward movement to the discharge height. The bars are usually rectangular.

Grate-cleaning system

Front comb linked on both sides to the drive system.